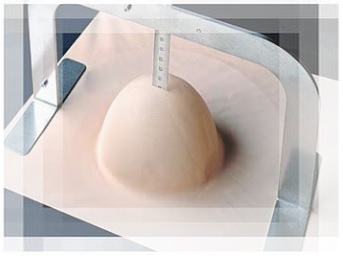

Molding

1/ Materials suitable for thermoforming:

It can be thermoformed almost all knitwear for the underwear and swimwear production, with the exception of certain laces and solid tulle. The most suitable for thermoforming are polyester knits and all elastic materials containing fiber Lycra. From our own materials suitable for thermoforming we have a long-term tested range of many types of fabric - such as tulle, including printed or embroidered (art. 506052, 506076, etc.), micro fabrics (art. 506634, 506665, 506731, etc.), heavy correction fabrics (art. 507001, 507010), cotton knits, etc.

2/ Testing of the fabric suitability from the customer:

For the correct machine settings (temperature, time), finding excessive yellowing and verification of the shape stability is required 0.5 mb of a fabric with a width of 150 cm.

If the type of fabric has already been thermoformed, so there is not needed any tests repeatedly. We provide free of charge the testing of the fabric suitability for thermoforming.

3/ Editing solution:

An integral part of the order is editing cuts of the molding fabric in a paper form.

If the customer does not have any cut in the paper form containing the size, final cut, the depth of a displacement, the marked place of the highest displacement, an orientation the materials in the product, so we are able to charge for a completely tune editing solution based on the information from the customer. We provide the editing solution both fully molding fabrics to produce unreinforced soft cups and under-pressure knitwear for application on the foam and other reinforcements.

4/ Yield:

Attained yield of the elastic material is in the range 9 -11 pairs/mb depending on the width of the fabric and the selected size of the mold. It can be also molded some of the types of the solid knitwear where the yield is in the ranges 6-7 pairs/mb.

5/ Delivery time:

There is a production date two weeks with the production of 3,000 pairs, and it is necessary to expect the delivery of the material to producers (the customer's own material), and return delivery of the finished cups to us. Basically, the real term is three weeks from the entering the order into the production. In case of repeating offtake then continuous supplies are according to previously advised needs.

6/ Payment Terms:

25% by the advance form before thermoforming and cutting the base material, the rest according to the agreed payment terms.

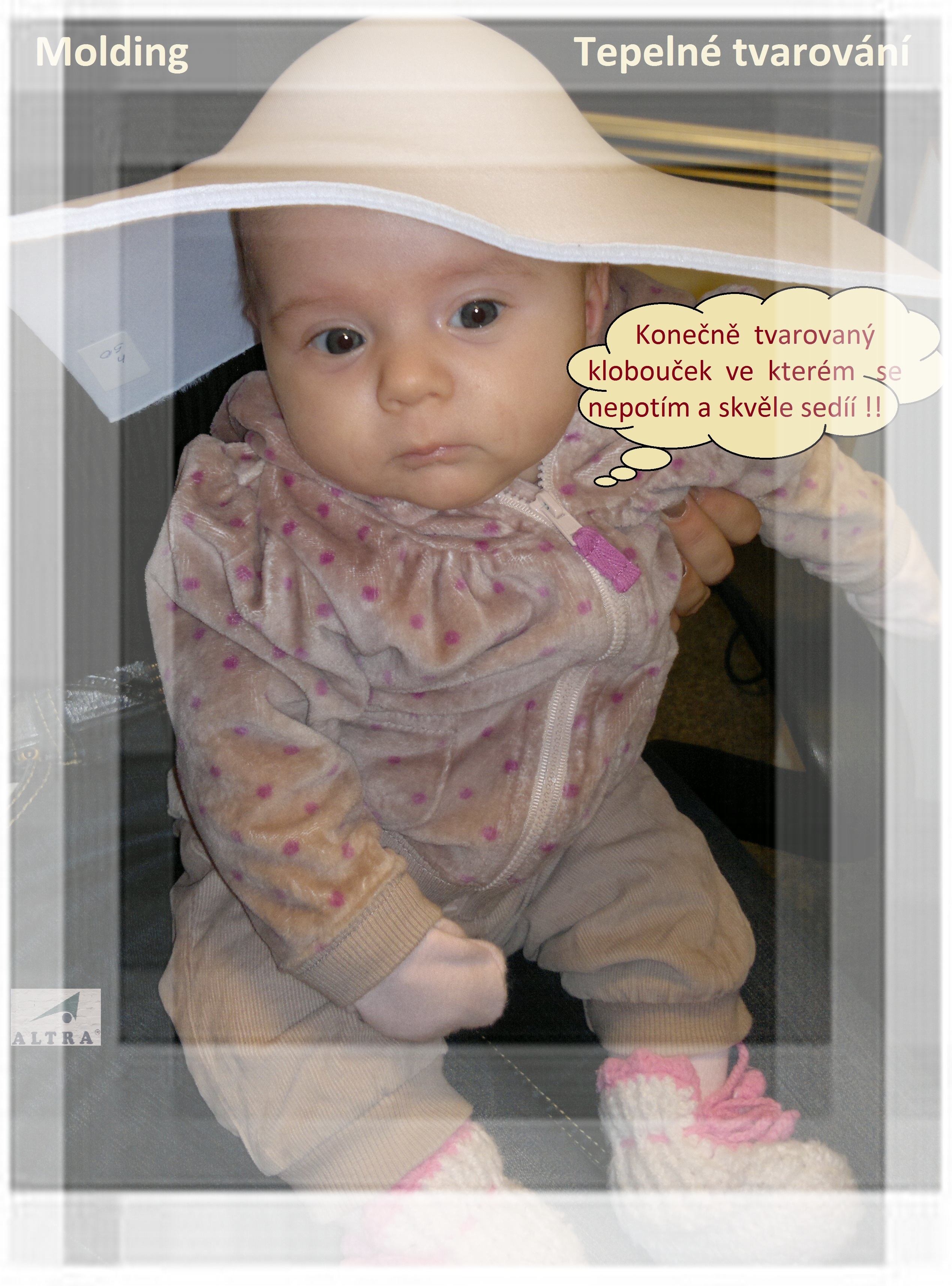

7/ Molding size (see the table 65B – 110B)